Inside Sellafield’s death zone with the nuclear clean-up robots

Robots only: inside here you’d receive a fatal dose of radiation within seconds

The Thorp nuclear reprocessing plant at Sellafield, Cumbria, has recycled its final batch of reactor fuel. But it leaves behind a hugely toxic legacy for future generations to deal with. So how will it be made safe?

Thorp still looks almost new; a giant structure of cavernous halls, deep blue-tinged cooling ponds and giant lifting cranes, imposing in fresh yellow paint.

But now the complex process of decontaminating and dismantling begins.

It is a dangerous job that will take decades to complete and require a great deal of engineering ingenuity and state-of-the-art technology – some of which hasn’t even been invented yet.

This is why.

Five sieverts of radiation is considered a lethal dose for humans. Inside the Head End Shear Cave, where nuclear fuel rods were extracted from their casings and cut into pieces before being dissolved in heated nitric acid, the radiation level is 280 sieverts per hour.

We can only peer through leaded glass more than a metre thick at the inside of the steel-lined cell, which gleams under eerie, yellow-tinged lighting.

This window is made from metre-thick leaded glass to protect humans from high-level radiation

This is a place only robots can go.

They will begin the first stage of decommissioning – the post-operative clean-out – removing machinery and debris.

Already, a mechanical arm on wheels is being carefully guided through the cave, as operators shout instructions to each other, trying to prevent the machine becoming tangled up in cables.

Once cleared, the cell will be washed repeatedly using water or acids to bring down the level of radioactivity. Ultimately, the plan is for humans to be able to enter the contaminated cave.

“We’ll need to look at novel decontamination agents to help us clean out the plant more effectively,” says Melanie Brownridge, head of technology at the Nuclear Decommissioning Authority.

Thorp: A brief history

Media playback is unsupported on your device

- Thermal Oxide Reprocessing Plant – Thorp – first conceived in the 1970s

- Cost £1.8bn, started operating in 1994

- Recycled used fuel from advanced gas cooled reactors (AGRs), extracting uranium and plutonium

- This extracted fuel would then be used in a new generation of super-efficient “fast-breeder” reactors that can “burn” plutonium

- But fast breeders never found favour and Thorp underperformed

- Processed 9,000 tonnes of used nuclear fuel in all, 40% from overseas

- Generated revenues of £9bn, says site operator Sellafield Ltd

- Ended operation November 2018

“That should help us remove more of the radioactivity early on, so that we can get on with the decommissioning job sooner.”

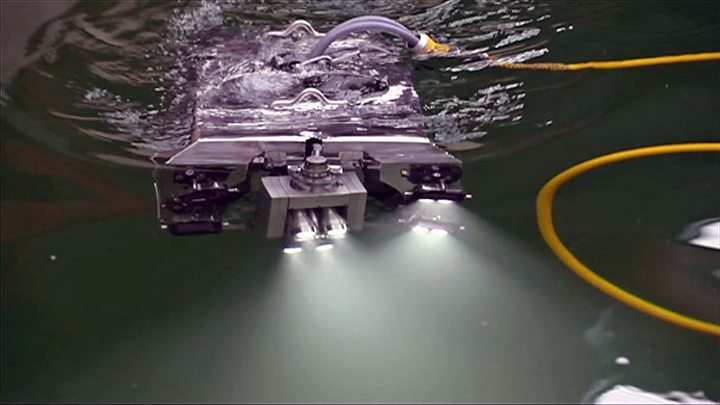

Cleaning up other parts of the plant will also need robots and remotely operated vehicles (ROVs).

Some will need to be developed from scratch, while others can be adapted from systems already used in other industries, such as oil and gas, car manufacturing and even the space sector.

“Some of these might be very small robots, able to change shape and go through small apertures into the facility,” explains Ms Brownridge.

“Others might be quite large devices used as platforms to take technology inside – so there will be a whole range,” she says.

Sellafield, and the engineering companies it works with, already have a great deal of experience developing technology for use in a highly radioactive environment.

The site in Cumbria contains a number of other redundant facilities, some dating back to the 1950s and many of them heavily contaminated, which are currently being decommissioned.

A flying drone has been used to map radiation in inaccessible parts of the site, for example.

Media playback is unsupported on your device

Remote submarines have explored and begun cleaning up old storage ponds. Other remote machines are being used to take cameras deep inside decaying bunkers, filled with radioactive debris.

The job of developing machines like these is shared with a large network of specialist companies, many of them based in Cumbria itself. They form part of a growing decommissioning industry within the UK, as the country grapples with the legacy of its first era of nuclear power.

The NDA believes that these companies can use what they learn at Sellafield, and other plants, to attract further business from overseas.

The drone mentioned above, for example, was developed by radiation-mapping specialists Createc and UAV company Blue Bear.

It is is now being used inside a damaged reactor building at the Fukushima plant in Japan.

Image copyright

Createc/Blue Bear

The Riser drone senses radiation levels in areas such as Fukushima in Japan

In this, the NDA has a surprising ally. The environment group Greenpeace, which bitterly opposed the opening of Thorp, is enthusiastic about decommissioning.

“We do feel it’s important that Sellafield confronts the decommissioning challenges that arise from Thorp’s closure,” says the organisation’s policy director, Doug Parr.

“In fact there’s a good case that people there can become world experts and world leaders in the decommissioning of nuclear power stations and other installations. We would support that.”

The post-operative clean out at Thorp is due to take three years, but the entire decommissioning process will take decades.

In the meantime, the plant will continue to serve a purpose.

For the next few years, one of its ponds will be used to cool and store used nuclear fuel – though that fuel will not be reprocessed.

Final demolition is expected to take place between 2075 and 2095, with the overall decommissioning bill forecast at £4bn at today’s prices.

But that isn’t the end of the matter.

Thorp leaves behind thousands of steel canisters filled with a glassy mixture of high level wastes – the by-product of years of reprocessing. Their contents will remain intensely radioactive for thousands of years.

Added to all this will be the wastes produced in the decommissioning process itself. They can be processed and packaged, in concrete and steel, but they cannot be destroyed.

Ultimately, the government’s policy is for intermediate and high level wastes – and potentially plutonium as well – to be stored within rock, hundreds of metres underground, in a so-called Geological Disposal Facility.

But “currently no sites have been selected or are under consideration”, the government says.

So while the clean-up at Thorp will soon begin, its hazardous remains will stay in Sellafield long into the future.